CNC, robots, industrial training help Freedman Seating

Automation, CNC, robotic welding help Freedman Seating with metal fabrication, as seen in a recent tour.

Learning Objectives

- 学习数控的应用,机器人焊接和满足al-forming processes at the Freedman Seating Co.

- See examples of manufacturing training at Jane Addams Resource Corp. (JARC) in Chicago.

- Learn the steps that lead from manual processes, to digitalization and finally to full-blown digital transformation.

Automated manufacturing insights

- Applications of CNC, robotic welding and metal-forming processes were described during a Freedman Seating Co. tour.

- Examples of manufacturing training were shown at Jane Addams Resource Corp. (JARC) in Chicago, co-located with Freedman Seating Co.

Freedman Seating Co.offered tours in association with theJane Addams Resource Corp. (JARC) Women in Manufacturing event, March 29.

While automated welding is part of the manufacturing process, manual welding also is needed. Welding, safety and CNC are among training certificationsJARCoffers in its onsite training facility at Freedman Seating Co.

Karen Arroyave, M.E., a Freedman Seating manufacturing engineer, gave the tour. She is working on a master’s degree to further advance manufacturing efficiency.

Multiple layers of fabric are cut using CNC-provided instructions at the Freedman Seating Co. location in Chicago. CNC also is used for some sewing (not shown). Courtesy: Mark T. Hoske, Control Engineering

The 130-year-old company employs about 650, including 30 in a plant in Indiana, and was in the process of hiring 50 more people as of the tour. Freedman Seating began manufacturing buggy seats and now makes seats for campers, buses, trains and ferries. Processes combine manual and automated techniques and robots, using fabric, padding, sheet metal to make tubing and bases to integrate with other materials to construct a diverse range of vehicle seats.

Lasertube metal tube forming machine makes tubes from flat steel at Freedman Seating Co. Courtesy: Mark T. Hoske, Control Engineering

Computer-numerical control, automated cutting, forming, welding

In the cutting department, many layers of fabric are cut to fit using CNC automated cutting machines. Sewing uses automated and manual machines.

Laser-welding tube fabrication cuts and welds tubing used for seats. Tube bending and cutting are automated, along with sheet metal cutting, bending and fabrication for seat bases.

A stack of metal tubes at Freedman Seating Co. awaits bending into seat shape. Courtesy: Mark T. Hoske, Control Engineering

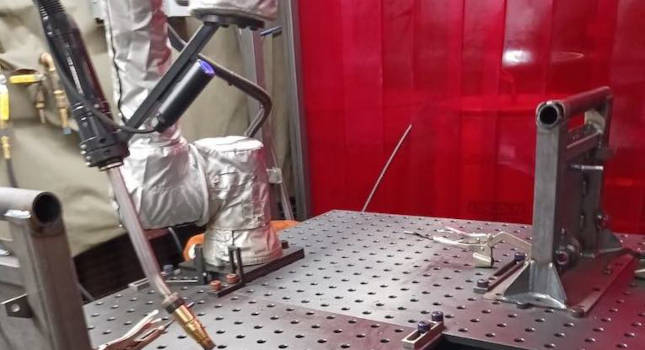

Vectis Automation provided two automated welding cells that work on seat bases using Universal Robots’ collaborative robots, wrapped for the application. (See photos below.)

Freedman Seating’s Karen Arroyave shows formed seat tubes prior to final bending. Courtesy: Mark T. Hoske, Control Engineering

Welding, CNC, 3D printing and other skills for manufacturing

The JARC manufacturing training portion of the tour included four welding booths, two CNC machines and a 3D printer that help teach manufacturing skills to those in need of higher-paying, more fulfilling careers than what they had. JARC also provides a wide range of manufacturing-related certifications, life skills and career training and placement at no cost to participants.

Stack of bent seat tubes looks like folding chairs at Freedman Seating. Courtesy: Mark T. Hoske, Control Engineering

Mark T. Hoskeis content manager,控制工程,CFE Media and Technology,mhoske@cfemedia.com.

KEYWORDS:Manufacturing tours, automation training

CONSIDER THIS

When seeingautomation applied in other locations, what will be your takeaway?

ONLINE EXTRA

See additional photos below.

Freedman Seating’s Karen Arroyave explains welding behind her. Courtesy: Mark T. Hoske, Control Engineering

Rolled steel, a little larger than a 4 by 8 ft sheet of plywood, awaits laser cutting at Freedman Seating Co. Courtesy: Mark T. Hoske, Control Engineering

Laser cutting pattern is optimized to minimize waste, said Freedman Seating’s Karen Arroyave. Courtesy: Mark T. Hoske, Control Engineering

A mallet can help separate laser-cut steel pieces at Freedman Seating. Courtesy: Mark T. Hoske, Control Engineering

Vectis Automation provided two automated welding cells (one shown) that work on seat bases using Universal Robots collaborative robots, wrapped for the Freedman Seating application. Courtesy: Mark T. Hoske, Control Engineering

Universal Robots’ collaborative robot in a Vectris Automation welding workcell welds behind a safety curtain at Freedman Seating Co. Courtesy: Mark T. Hoske, Control Engineering

Applied welding expertise: Freedman Seating Co. fabricated and welded the welding hoods for the two collaborative welding robot workcells. Courtesy: Mark T. Hoske, Control Engineering

许多类型的座椅生产完成b之一y Freedman Seating Co. Courtesy: Mark T. Hoske, Control Engineering

Personal protective equipment needed for various manufacturing processes, including welding, is among training offered by Jane Addams Resource Corp. (JARC) at its training center co-located with Freedman Seating Co. in Chicago. Courtesy: Mark T. Hoske, Control Engineering

Welding booth and exhaust hood are shown at the Jane Addams Resource Corp. (JARC) at its training center at the Freedman Seating Co. location in Chicago. Courtesy: Mark T. Hoske, Control Engineering

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Clickhereto start this process.