Automate 2023 Day Two: Optimize and simplify manufacturing applications

Manufacturers at Automate 2023 are emphasizing products that can perform complex tasks, but are designed to be simple and easy to use.

Manufacturing optimization insights

- Manufacturing technologies are getting more sophisticated in their capabilities, but they’re also getting easier to use so they’re more accessible.

- Collaborative robots are taking on more industrial robot capabilities, but are still able to work in tandem with humans as needed.

- Digital twin technologies and large language models (LLMs) such as ChatGPT also are helping make engineers’ lives easier.

Manufacturing technologies are getting more sophisticated and are capable of performing more tasks than ever. They are designed to not only perform their basic functions, but also provide additional capabilities that allow them to work in multiple environments and withstand many potential challenges.

At the same time, they are designed to be simple to use and execute. While it might seem impossible and contradictory, these are the expectations users have and manufacturers are following along.

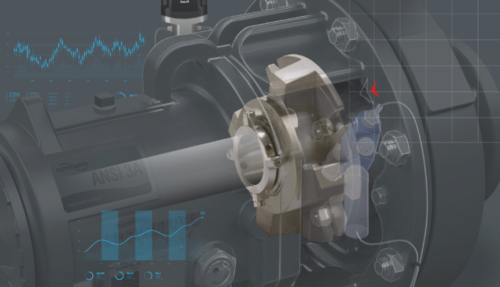

Alan Freeman, an electromechanical engineer at Schneider Electric, explained how the TeSys Island digital multifunctional load management solution is designed to manage motors and make them perform better as well as give users better insights.

“The idea is most motors are not smart and when something goes wrong, you don’t know why they fail,” he said. Scaling up with a variable frequency drive (VFD) is expensive, which is where the island comes in. It is designed to connect up to 20 motors per bus coupler with one module and the programmable logic controller (PLC) can communicate like an edge device. This can give the user in the control room a more comprehensive view of what’s happening and what might or will happen down the road. This is a critical aspect becoming mandatory for manufacturers looking to reduce downtime.

“It’s about being more predictive and getting the right data and information to the user to make better decisions,” Freeman said.

Martin Buena-Franco, automation products marketing manager for The Raymond Corporation, said their approach to the material handling market is about engaging the customer’s needs.

“We engage with the customer and ask what their pain points are, what key performance indicators (KPIs) they are trying to achieve and what constraints they have. We optimize and utilize lean techniques and try to get closer to meeting those KPIs.”

They use telematics to help them in this journey, he said, by gathering all the data and capturing the data from their product and the facility it’s operating in to paint a picture.

“When it doesn’t quite reach what we’re hoping, we tweak it again,” Buena-Franco said. “Automation is about optimization.”

Kevin Corcoran, product manager at Lenze, described their i950 cabinet servo inverter as a solution that comes prepared for the user. “A lot of the code is prewritten and is designed to run advanced applications right out of the box. The user has to handle the parameters, but it is designed to be less complex at the same time.”

Jessica Ragzy Ewud, a contemporary artist and LEGO master, built a full-size LEGO replica of the ABB CRB 1300 Swifti collaborative robot at the ABB booth with some help from the Swifti and an ABB Flex Feeder robot. Courtesy: Chris Vavra, CFE Media and Technology

Creating manufacturing building blocks

ABB Robotics’ booth emphasized LEGO as a metaphor for building the future of manufacturing and developing stronger and better automation solutions. They even had Jessica Ragzy Ewud, a contemporary artist and LEGO master, build a full-size LEGO replica of their CRB 1300 Swifti collaborative robot at the ABB booth with some help from the Swifti and an ABB Flex Feeder robot.

“The Swifti is an industrial robot with collaborative features,” said Mark Ruth, senior project engineer of automation for ABB Robotics, adding it is useful for palletizing, automotive and other applications requiring a robot to move quickly, but allows for human interference, as needed.

At the nearby Rockwell Automation booth, they were displaying Emulate 3D, which is a 3D physics-based modeling environment designed to provide a digital twin of all machines.

“Our tools are designed to turn these concepts into digital machinery,” said Michael Sarvo, digital design business development manager for Rockwell Automation. “Users can also test the control logic against the digital machinery using virtual reality tools.”

除此之外,模拟3 d允许用户创建the ideal factory through the digital twin and they have many different options and settings to make this happen. Sarvo agreed the process was very much like putting a couple of LEGO pieces together.

“你把它放在一起,他们突然像乐高玩具,”他said. “This lets you try out all of your what-ifs and see what is and isn’t possible.”

Beckhoff Automation’s booth imagined building blocks in a different way. They are augmenting their TwinCAT Chat Clients, which makes it possible to use large language models (LLMs) such as ChatGPT. It provides a user interface and provides communication to the programmable logic controller (PLC) development environment via the automation interface.

“You can set the variables and the calculation form and it’s created the function for you,” said Daymon Thompson, director of product management at Beckhoff Automation.

While in the early stages, Thompson said it will only get smarter because its capabilities and knowledge is based on the web.

Beckhoff Automation’s TwinCAT Chat Clients can use large language models (LLMs) such as ChatGPT to speed up coding applications for engineers. Courtesy: Chris Vavra, CFE Media and Technology

“With more content and more work, it will get smarter,” Thompson said.

At Automate, the idea of a “what-if” is becoming more of a “what-can-I” proposition as the lines between industrial and collaborative, digital and physical and so much more are blurring into one another.

与此同时,他们使它更简单和easier for engineers to use.

Chris Vavra, web content manager, CFE Media and Technology, cvavra@cfemedia.com

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Clickhereto start this process.