More answers about how to build a better HMI with collaborative, modern, cloud technology

Experts provide more answers about human-machine interface (HMI) design. The related May 11 webcast is archived for a year.

Human-machine interface (HMI) automation design experts provide more answers about how HMI design, use and operation, after the Control Engineering May 11 webcast, “Build a better HMI with collaborative, modern, cloud technology,” that will be archived for a year. Audience listening live had the opportunity to submit questions to presenters. Some answers include information on HMI design software features, HMI scripting, cloud use to improve HMI design and version tracking.

Webcast presenters on HMI, visualization software

专家们在网络直播和提供额外的answers were Steve Briant, visualization platform lead, Rockwell Automation, and Mark Hobbs, software senior product manager, (photos) Rockwell Automation. The learning objectives for the webcast were:

Learn how to harness the cloud and become more agile through collaborative engineering

Understand how to create your application and deploy to any device

Learn how to style your HMI graphics for a global audience

Explore how to build from the ground up with OPC UA and incredible extensibility that supports Industry 4.0.

Briant and Hobbs provided answers below, lightly edited for magazine style. Products mentioned are from Rockwell Automation except as linked; find registration and trademark information on the Rockwell Automation product pages below.

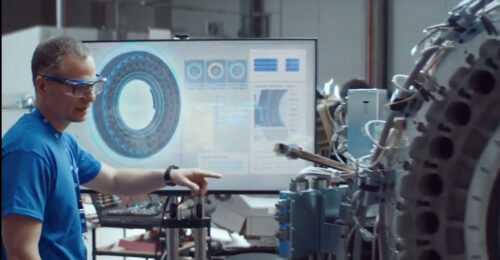

Steve Briant, visualization platform lead, Rockwell Automation, and Mark Hobbs, software senior product manager, Rockwell Automation, answered additional questions after the webcast “Build a better HMI with collaborative, modern, cloud technology.” The May 11 Control Engineering webcast is archived for a year. Courtesy: Rockwell Automation, Control Engineering webcasts

Questions on HMI design

Question: About HMI scripting: Are there any automated conversion processes that can take HMI displays from one process to another?

Answer:Yes, HMI displays can be imported, via scripting, both during design and runtime. FactoryTalk Optix has participated inMTP BioPhorumplug-and-play tests, importing complete graphical presentations of process skid equipment while running.

Q: Can your HMI run also on Android-based devices?

A:FactoryTalk Optix supports both an on-premise client and HTML client. The HTML client provides an effective way to connect to a FactoryTalk Optix system using a web browser from a remote PC or mobile and tablet devices.

Q: Please provide advice about HMI screen development.

A:FactoryTalk Optix Studio is the integrated design environment used to create screens for FactoryTalk Optix applications. Development can also take place outside of the FactoryTalk Studio graphical interface through anOpen APIand scripting interface to auto generate project content. The UI itself is flexible and supports many navigation styles based on the needs of the application. Screen development can be further enhanced using an object-oriented type / instance model where types can be centrally managed and changes propagated to instances. Lastly, FactoryTalk Optix supports an extensive library of graphics, widgets and faceplates to get you started.

Questions on HMI integration with other automation

Q: In the quick start demo, how do you tie a start and stop push button and motor graphic to a direct connected automation controller database (ACD) file in a 5580 controller?

A:FactoryTalk Optix从一个ACD文件可以导入标签both offline or online with the controller. Once imported into FactoryTalk Optix, the tags can be bound to graphics and objects used in the project. There is also an Alias feature within FactoryTalk Optix, which can be used to tie all tags in a reusable object, such as a motor widget, to a structure in the controller.

Q: Can we use the operating system in series B PanelView to run FactoryTalk Optics?

A:No, PanelView Plus 7 are designed for FactoryTalk View ME and are closed (cannot be modified) to run other packages.

Q: What types of manufacturing devices can be connected to the system and visualized on it? Is there a specific set of requirements for a protocol?

A:FactoryTalk Optix can read/write devices across the top industrial protocols. Custom drivers can be written in C# in cases where industry standards are not applicable. In addition, open protocols likeOPC UAandMQTTcan be used to communicate with certain devices.

Q: What about CC-Link driver?

A:We will consider adding this protocol to our plan.

Q: Does FactoryTalk Optix replace FactoryTalk View Studio, even the SE and the ME?

A:FactoryTalk Optix and FactoryTalk Optix Studio are an addition to our portfolio. FactoryTalk Optix does not replace any of our current portfolio of products.

Q: Please explain more about HMIs can help with BACnet use and connection to control points, objects, inputs or outputs.

A:BACnet [from ASHRAE]is a protocol supplied on many building automation devices. FactoryTalk Optix will interact with these types of devices the same as other automation devices, including Rockwell Automation controllers. A BACnet Comm Driver is in progress (beta this summer) and will be delivered in our October 2023 release.

Q: How can this help with generator monitoring and power relay modules?

A:通过通讯Dri FactoryTalk Optix连接到设备vers to enable reading / writing of variables in those devices. Screens can be created to visualize data, buttons can be created to set values. Alarms can be created and monitored. Integration with power generation can also be integrated with main control systems or building management systems.

Q: If we design our custom automatic test tools, what do we need to include in the design to be able to interface with FactoryTalk Optix?

A:We use automated test tools with all our products, include FactoryTalk Optix. FactoryTalk Optix’s extensive APIs and open text project format make it ideal for automating development and testing workflows. Connect with us so we can better understand your workflows and discuss how FactoryTalk Optix can help you achieve your goals.

Questions on HMI software linking to cloud services

Q: How can the software help harness cloud capabilities?

A:FactoryTalk Optix can be run in the cloud, accessible from the FactoryTalk Hub, using a web browser. FactoryTalk Optix applications can be deployed from the cloud to devices using a FactoryTalk Remote Access VPN connection. FactoryTalk Remote Access is integrated with FactoryTalk Optix Studio for remote deployment.

Q: Please discuss array management with Optix, API rest management, HTTP Post to inject to InfluxDB Cloud. And HTTP POST to inject to Fiix.

A:FactoryTalk Optix has an information model that fully supports OPC UA defined data types, including arrays and structures. FactoryTalk Optix can be extended with REST to integrate with any typical cloud-based application like Plex Systems [native cloud smart manufacturing software from Rockwell Automation] or Fiix [computerized maintenance management system (CMMS) from Rockwell Automation].

Questions about HMI software capabilities, change management

Q: This push-pull interaction means it is not real-time, as one would see during something like a document edit via Microsoft SharePoint, correct?

A:The status and indicators of the multi-user collaboration / integrated version control management features of FactoryTalk Optix Studio are updated “immediately” when an action takes place. The user, seeing the status change, must take the action (push, pull, resolve conflicts, etc.)

Q: What happens with conflicting changes?

A:Conflicting changes are highlighted, along with action that the user can take to accept individual conflicts or address them all with one click (accept all local/reject all local).

Q: Are there PLC number limitations, say 500 devices? Tag limits?

A:No, there are no limits to devices or tags. FactoryTalk Optix is licensed by features, more directly, feature packages, from XS (5 features) to XL (21 features) … and even an unlimited feature package.

问:有时间的时候我们可以使用工厂Talk Vault as a repository and GitHub?

A:We are working on different options to allow FactoryTalk Optix projects to be added to a FactoryTalk Vault Solution later this year.

Q: Can multiple users have different screens open?

A:Yes, each user opens a unique session and can display and interact with different content.

What are the improvements for the new HMI version, does this software provide trends and for how long back can the data be referred to?

A:FactoryTalk Optix has a Trend control, which can be configured to show both real-time or historical data retrieved via our ODBC connector. FactoryTalk Optix also includes an embedded database for storing data locally within the constraints of the storage capacity of the device. FactoryTalk Optix also can store data remotely, into any ODBC data store.

Is the ability to call an HMI display page from the PLC included?

A:Yes. In fact, we have some nice “System Variables” that will be releasing soon that let you configure a PLC variable to see the current screen or write to change the current screen.

Questions on learning more about FactoryTalk Optix HMI software from Rockwell Automation

Where can I find more information on FactoryTalk Optix?

A:https://www.rockwellautomation.com/en-us/products/software/factorytalk/optix.html

I’m interested in trying out FactoryTalk Optix Studio. How do I access it for free?

A:Go tohttps://www.rockwellautomation.com/en-us/products/software/factorytalk/optix/try-it-now.html

Please explain more about programming and navigation within the system.

A:Training materials are available from Rockwell Automation and distributors. There is also an online help area that includes a quick start guide. YouTube videos cover basic concepts herehttps://youtube.com/playlist?list=PL3K_BigUXJ1M1-JpRiwIIhzJUbhwtK3yy

Is the pricing structure available from the Rockwell Automation website?

A:Yes. There is also a sizing tool on FactoryTalk Hub under the FactoryTalk Optix tile that will help you sort out which “feature package” is right for your application.

Edited by Mark T. Hoske, content manager,Control Engineering,CFE Media and Technology, and webcast moderator,mhoske@cfemedia.com.

KEYWORDS: Human-machine interface, HMI design, HMI integration

LEARNING OBJECTIVES

Understand more HMI designquestions and answers resulting from a May 11 Rockwell Automation FactoryTalk Optix software webcast.

Learn more about HMI integrationwith other automation, HMI software capabilities, change management and cloud capabilities.

CONSIDER THIS

Is your currentHMI design software meeting your needs?

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Clickhereto start this process.