NewTek Sensor Solutions

Products

Air extend/spring retract gage head sensors

NewTek GAR Series Spring-loaded Gage Heads are used in automated dimensional gaging applications as part of the inline inspection processes, when it is ideal for the sensor probe to move out of the way between readings. The probes of these LVDTs extends when taking dimensional measurements, and then retract to their original position to avoid damage to the sensor or next conveyed product. In manufacturing conveyor lines, these air extend/spring retract gage heads conduct tolerance checks as part of quality assurance measures. The LVDTs provide dimensional feedback to verify if parts have any variance in size and other physical properties.

Hazardous location position sensors ensure accurate valve position in chemical plants

Major chemical companies are using hazardous location position sensors from NewTek Sensor Solutions to monitor the state of different valves throughout their plants as part of process safety and efficiency management. Chemical plants using potentially explosive substances in their processes utilize different valves to control flow. Operators constantly monitor valve performance to determine if they are operating to specifications for optimal efficiencies. NewTek HL-750 series of intrinsically safe position sensors monitor valve position in the harsh and hazardous environments of chemical plants, providing highly accurate displacement feedback to determine if valves are properly opened/closed, leaking or have failed. Certified for use in Class 1, Zone 0, Zone 1 and Zone 2 locations, the AC-operated position sensors operate safely and accurately in hazardous locations with flammable or ignitable liquids and gases.

Custom position sensor that detects part errors in automotive resistance welding machines

NewTek Sensor Solutions has designed a custom linear variable differential transformer (LVDT) position sensor for resistance spot welding machines used in automotive plants to detect missing or misaligned parts in nut and stud welding. Cars contain hundreds of welded nuts and studs that hold them together. Properly securing the right nut and stud to different car components is critical to safe operations. Working in conjunction with the resistance weld control equipment, the NewTek custom LVDT detects and reports different conditions including: weld pin extended position, double part, misloaded part, incomplete weld, weld pin retraction, upside down nut, wrong or missing part. Based on programmed system spec limits, the position sensor will trigger a go/no go response with each pass. Designed to fit inside the weld body of the machine, the AC-operated LVDT sensor has a very high stroke length ratio and excellent repeatability that is critical to the application.

AC-LVDTs serve as alternatives to magnetostrictive sensors

NewTek AC-operated LVDT position sensors often serve as a more reliable, precise and cost-effective alternative to magnetostrictive linear position sensors in the monitoring and control of valves in power generation and hydroelectrical stations. Because power generation environments can reach temperatures of 250°C (475°F), magnetostrictive technology might fail or become inaccurate over time. While very accurate in benign applications, most magnetostrictive sensors cannot operate over 85°C as electronics must be placed very close to the wand. With electronics separated from the LVDT coils, NewTek’s AC-operated linear position sensors continuously operate in power generation stations without failure at high temperatures. While the LVDT sensor remains in a harsher environment, NewTek’s NTC-6000 LVDT Signal Conditioner (which excites the AC-operated LVDT and provides a variety of output options for use in PLCS and other control systems) operates in a less innocuous environment.

自定义位置传感器与发泄身体满足了hole drilling application requirements

NewTek recently designed its 100th custom LVDT Position Sensors with a vented body and modified lead lengths to address the unique operating specifications for a downhole drilling application. Venting NewTek’s NT-R High Temperature Sensor ensured reliable performance in a downhole drilling tool that operated in a high-shock environment with pressures up to 10,000 psi and temperatures up to 400°F (200°C)). By venting holes in the housing, the sensor can equalize pressure inside and outside to operate reliably in temperature extremes of -65°F to +400°F and operating pressures of 30,000 psi. As most sensors often do not meet application requirements for position measurement right out of the box, NewTek has the engineering and domestic manufacturing capabilities to customize versions of its standard AC- and DC-operated LVDT Position Sensors to meet unique operating and configuration specifications. Customizations may include radiation and submersion resistance, higher temperature exposures, ratiometric output, high stroke-to-length ratios, specific electrical output requirements, ceramic and special core materials, and the use of special alloys such as monel, inconel, hastelloy and titanium in the construction of the sensor body. NewTek offers sensor customization for different industries including oil/gas, aerospace, subsea, R&D testing, packaging, turbine, pharmaceuticals and others.

Spring-Loaded Position Sensors

NewTek spring-loaded LVDTs provide ultra-precise dimensional measurement of high-volume molded automotive parts in plastic mold testing. Different interior, exterior, and mechanical automotive parts, such as bumpers, heating components, and door handles, are manufactured through an injection molding process. To ensure product consistency, quality, and adherence to federal and state standards, the molded parts are tested for defects.

LVDT position sensors for critical energy sector applications

The energy sector uses NewTek LVDT Position Sensors as metrology tools in ensuring the proper operation of different power systems. For example, position sensors monitor gas turbine servo controls, fuel valve position, and micro fuel valve openings in the operation of gas turbines. To reliably perform in these critical applications, NewTek often customizes its LVDT displacement sensors to meet customer’s sometimes non-standard operating parameters. By tailoring sensors to operate within specific specifications, customers do not need to conduct expensive design reviews of standard position sensors or worry about meeting safety regulations and codes. To conform an LVDT to meet the needs of a critical application, NewTek can expand temperature ranges, tighten impedance specifications, and use different sealing methods and housing materials such as Inconel, Hastelloy and Titanium. For applications with high shock and vibration levels, NewTek can vacuum varnish and epoxy encapsulate an LVDT position sensor. For environments with extreme temperature ranges such as those in engine control systems, NewTek can construct its displacement sensors with ceramics and special core materials to meet temperature requirements up to 1000°F.

Medical Sensors

NewTek医疗传感器承受非盟的影响toclave cycles used to sterilize medical equipment prior to surgical procedures or other medical uses. According to the Centers for Disease Control , steam sterilization, as accomplished in an autoclave, is the most widely used and dependable method of sanitizing critical medical equipment as a part of infection control. Embedded within medical devices, NewTek linear position sensors play a critical role in the safe and accurate performance of healthcare equipment used in patient care. A small size, large measurement range, accuracy and resistance to environment effects make them ideal for medical devices, especially those frequently sanitized in autoclaves that use pressurized steam or another gas to perform sterilization. For example, the NewTek M-375 Series Miniature AC LVDTs popularly serve as components within medical devices as they are highly resistant to harsh and high-pressure environments and offer a compact 3/8” diameter size to fit in tight space restrictions. With a corrosion-resistant, nickel-iron alloy housing and core, these sensors can operate in temperature extremes of -65°F to +400°F. NewTek also provides customized LVDTs tailored to withstand repeated autoclave cycles depending on the customer’s sanitizing requirements. In one medical device application, NewTek LVDTs serve as a component for a bone drill, delivering feedback on the depth of drilling to tenths of a millimeter so surgeons can accuratel.

Quik-Cal™ LVDT Signal Conditioner Sets a New Standard in Reliability and Ease-of-Use as Part of Signal Processing System

NewTek传感器解决方案提供了最先进的一个nd user-friendly signal conditioner that pairs with AC-operated linear and rotary position sensor to deliver reliable feedback in DC voltage, current and digital outputs for use in factory automation, materials testing, packaging, and dimensional gaging applications. Offering an intuitive set-up of AC-operated LVDTs and RVDTs in process control systems, the signal conditioner features LED front panel null indicators and push buttons to set zero and full-scale output positions. With simple setup instructions printed on the unit’s label and color-coded removable terminal blocks, the NTC-6000 is configurable in just minutes even by non-technical personnel. Units offer automatic excitation synchronization for multiple unit systems. The smart NTC-6000 Signal Conditioner diagnoses and indicates LVDT failures, disconnects or short circuits for fast resolution of problems. Cybersecurity lockout and tamper detection ensures its safekeeping in locations without supervision. The LVDT signal conditioner incorporates a two-wire RS-485 digital communications port and offers hot swapability so setup can be saved and reloaded via the RS-485 port.

Hermetically Sealed 4-20 mA Position Sensors Offer Consistent Performance with Low Power Consumption

NewTek传感器解决方案提供了其气aled Position Sensors with a 4 – 20 mA current loop output that has become the data transmission standard in the process control industry. Offering rugged operations and high performance with low power consumption, Newtek’s HI Series of Hermetically Sealed 4-20 mA LVDTs ensure highly reliable and consistent data output for factory automation, materials testing and packaging equipment applications. Requiring less power than similar DC-operated LVDTs and signal conditioners, these 4-20mA sensors also satisfy low power budgets. Sustaining accuracy with no errors over long distance transmissions, the 4 – 20 mA current does not degrade over long connections and is less sensitive to background electrical noise. Simple to connect and configure, the 4-20 mA output position sensors offer plug and play compatibility with most PLCs and controllers.

Hazardous Location Linear Position Sensors

NewTek Hazardous Location Position Sensors monitor the structural integrity of LNG tanks, helping to meet Federal Energy Regulatory Commission (FERC) regulations for structural health monitoring. To prepare LNG for export, natural gas is cooled to cryogenic temperatures at liquefication facilities, then stored as a liquid until pumped into LNG tanker ships for export. The LNG storage tanks are double- walled, consisting of an inner container that holds the liquid and an outer container of vapor pressure that insulates it and serves as a backup in the event of a leak.

LVDT Position Sensors for Vibroseis Trucks

Seismic surveys are a popular non-invasive method used by exploration companies to search for oil and gas below the Earth’s surface. The testing is conducted with vibroseis trucks that deliver a low frequency vibration from a seismic vibrator using a base plate that impacts the earth. With every sweep, outgoing vibration signals from the trucks impact the ground at varying speed and frequency.

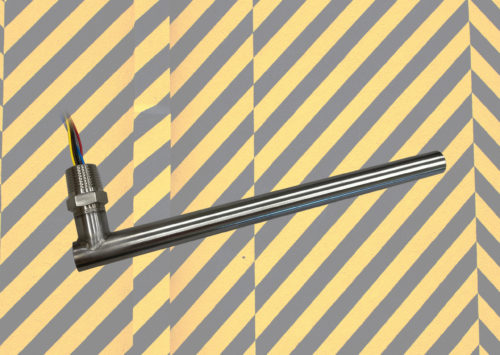

Hazardous Location LVDTs

Newtek Sensor Solutions introduces a new line of Hazardous Location LVDTs (Linear Variable Differential Transformers) that operate safely and accurately in hazardous and explosive environments with the presence of flammable or ignitable gases and liquids such as those found in refining and petrochemical plants, pipelines and oil and storage tanks. Approved for used in Class 1, Zone 0 and Zone 2 locations, the NT-HL-750 series of LVDT Position Sensors are ideal for pipeline and LNG storage tank structuring monitoring and real-time position sensing of different valves in oil and gas fields, chemical process plants, gas turbines and oil refinery platforms and rigs. These AC-operated sensors also are Intertek approved and hold an ETL mark that certifies its use in hazardous locations throughout North America.

LVDT Position Sensors

NewTek Pre-calibrated Linear Position Sensors serve as long-term replacements for potentiometers (pots) that become unreliable over time due to their contacting operation and effects from vibration and other environmental parameters. As potentiometers rely on mechanical contact to provide position feedback, components wear out and are affected by heat, vibration, and humidity, making output progressively noisier and unreliable over time. Non-contacting and with no parts to wear out, NewTek LVDT Position Sensors offer frictionless operation and do not drift or get noisy even over extended periods. The excellent repeatability, temperature resistance, and resolution of LVDTs are critical for industrial applications that require measurement of very small movements such as TIR measurements, thermal expansion, and dimension quality. (see chart and caption) Challenging operating conditions such as high shock and extreme temperatures also can limit a potentiometer’s performance and reliability. As a result, Mean Time Between Failure (MTBF) is typically lower for a potentiometer operating in a moisture-free and low vibration environment, than an AC-operated LVDT Linear Position Sensor working in a demanding application.

AC-LVDTs

NewTek Hermetically-Sealed AC-operated LVDTs enable safe position measurement in high-risk areas to protect operators from harm. Constructed without internal electronics, AC-operated LVDTs operate reliably in industrial applications with high, low or unpredictable temperature fluctuations, shock, vibration, and chemical, or radiation exposure. While the AC-operated LVDTs operate in a hostile area, feedback is retrieved by an LVDT Signal Conditioner that converts it to a digital signal for use in a computer or programmable logic controller located in a benign area. For example, LVDT Position Sensors used in the process control systems of paper mills provide dimensional feedback on the tension arm or roller position to control product thickness. The paper mills pose dangers to operators with larger rollers moving at high speeds, caustic and corrosive fluids splashing in unpredictable places, and temperatures fluctuating at different points in the process. Legacy mechanical position inductors or dial indicators used for position measurement may require an operator to approach the measured object. In addition to risking exposure to hazardous conditions, measurements may be hard to access in tight spaces or close to operating machinery.