PLC, SCADA upgrades improve fermentation process for winery

加州酒厂需要现代化的控制器ls for their red fermentation process with a PLC and SCADA upgrade.

过时的控制可以构成许多操作challenges. Companies that operate with outdated controls often experience frequent downtime, expensive or obsolete hardware replacement parts, or few personnel with knowledge to perform maintenance on legacy systems. These challenges were faced by a California winery who needed to modernize the controls for their red fermentation process. The winery needed to address how a system upgrade would impact their operations and engaged Automation Group to create a programmable logic controller (PLC) and supervisory control and data acquisition (SCADA) upgrade solution.

Developing a documented project plan

The first step was to create a well-documented project plan. The existing system design was analyzed and detailed existing hardware components, software configurations, and network connections. This step was crucial to have an accurate picture of their current control environment to mitigate production impacts during the implementation phase.

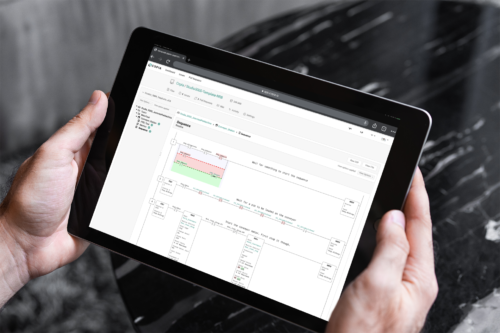

The project team upgraded hardware and reconfigured the customer’s existing SCADA software for seamless post-upgrade operations. The original red fermentation process was conformed with three areas: Pump over area, continuous press area, and decanters area. Previously, each area had their own PLC but the upgraded system connected a PLC as the main controller and remote IO was added to control the three areas into one. The system was programmed with ladder logic to the customer’s existing SCADA software, and seven human-machine interfaces (HMIs) were also programmed with visualization software.

The project team leveraged their PLC programming, SCADA software, and controls engineering expertise to resolve software compatibility issues, bugs in the programming code, and electrical connection challenges. The team supported the project to resolve these challenges and performed extensive testing. With the PLC and SCADA upgrade complete, the customer was able to improve the uptime of its red fermentation process and eliminated the key challenges of legacy system maintenance.

–Automation Groupis a CFE Media and Technology content partner.

Original content can be found atAutomation Group.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Clickhereto start this process.